Collection:

Juneau—Douglas City Museum

Object ID:

2007.22.142 A—B

Accession#:

2007.22

Credit Line:

Transferred from the U.S. Bureau of Land Management.

Object Name:

Separator, Washer

Title:

Laboratory Floatation Machine

Date:

04/15/1953

Year Range from:

1953

Year Range to:

1996

Description:

Floatation Machine

A — Object is a heavy cast steel tank on top of a steel plate. The proper left side of the tank is made of glass. On the proper right side of the tank is printed the following in raised letters: "500 GR / DENVER LAB / FLOATATION MACHINE " There is also a small Denver Equipment Company identification tag in red and blue, it is engraved with the number" EW 26797." Mounted to the back of the object is an electric motor. There is an identification on the motor indicating that it was manufactured by Baldor Elecric Company in Saint Louis, MO. It is a 500 RPM motor. On the proper left of the object is a power control switch that was manufactured by General Electric in Schenectady, NY.

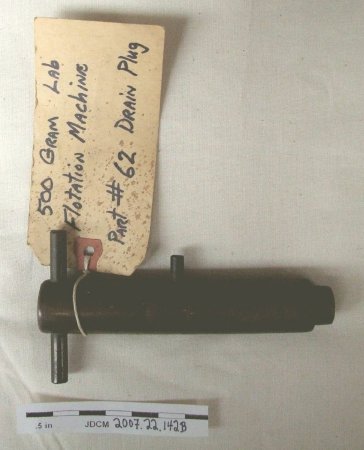

B — Brass Plug. This is a drain plug that goes into the bottom of the tank (A). It is made from brass rid 7/8" in diameter and 5 3/8" long. It is shaped in the general form of a cross, with a handle made from a brass rod, going through the main rod near the top. There is a second brass rod protruding from one side of the object half way down the main shaft. The bottom of the rod is stepped down and there is a synthetic washer around the nipple on the end.

A — Object is a heavy cast steel tank on top of a steel plate. The proper left side of the tank is made of glass. On the proper right side of the tank is printed the following in raised letters: "500 GR / DENVER LAB / FLOATATION MACHINE " There is also a small Denver Equipment Company identification tag in red and blue, it is engraved with the number" EW 26797." Mounted to the back of the object is an electric motor. There is an identification on the motor indicating that it was manufactured by Baldor Elecric Company in Saint Louis, MO. It is a 500 RPM motor. On the proper left of the object is a power control switch that was manufactured by General Electric in Schenectady, NY.

B — Brass Plug. This is a drain plug that goes into the bottom of the tank (A). It is made from brass rid 7/8" in diameter and 5 3/8" long. It is shaped in the general form of a cross, with a handle made from a brass rod, going through the main rod near the top. There is a second brass rod protruding from one side of the object half way down the main shaft. The bottom of the rod is stepped down and there is a synthetic washer around the nipple on the end.

Notes:

2007.22.142A has not been labeled.

This machine was installed when new on a counter in the Ore Lab by Mike Blackwell. It was made by Denver Equipment Company and sent on April 15, 1953 with detailed schematics. See the document file for detailed paperwork about construction, erecting and maintenance of the machine.

It is basically a blender and a small version of floatation machines that are used in production operations. Ore and water with reagents specific to the content of the ore are added to the tub where the paddle is. The paddle agitates the mixture. Air is pumped in, the air in association with the combination of reagents makes the mixture bubble. Flakes of the mineral you are testing for adhear to the frothy bubbles. The bubbles can than be scraped off of the mixture and into an enamel tray that is placed under the chute. Then both samples of ore can be assayed for content.

This machine was installed when new on a counter in the Ore Lab by Mike Blackwell. It was made by Denver Equipment Company and sent on April 15, 1953 with detailed schematics. See the document file for detailed paperwork about construction, erecting and maintenance of the machine.

It is basically a blender and a small version of floatation machines that are used in production operations. Ore and water with reagents specific to the content of the ore are added to the tub where the paddle is. The paddle agitates the mixture. Air is pumped in, the air in association with the combination of reagents makes the mixture bubble. Flakes of the mineral you are testing for adhear to the frothy bubbles. The bubbles can than be scraped off of the mixture and into an enamel tray that is placed under the chute. Then both samples of ore can be assayed for content.

People:

Blackwell, Mike

Search Terms:

JMIC

T&E

Mine

Mining

Assaying

T&E

Mine

Mining

Assaying

Subjects:

Laboratories

Ore industry

Assaying

Assayers

Ore industry

Assaying

Assayers